Table Of Content

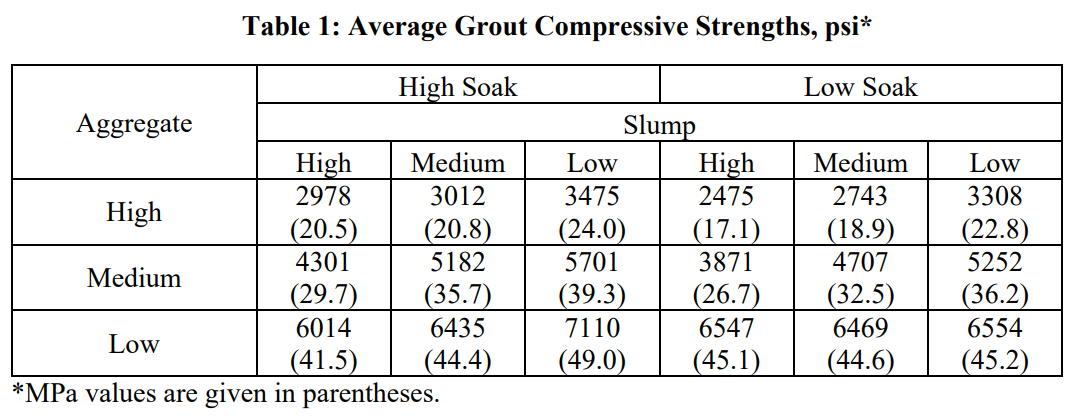

There are many grade of nominal mix concrete like M-5, M-7.5, M-10, M-15 and M-20. Design mix – Design mix is a process to prepare concrete by testing all necessary properties (like properties of cement, fine aggregate and coarse aggregate) of concrete ingredients. Establishing quality control processes is also important for mastering concrete mix design. This involves testing the concrete mixes and ensuring they meet the desired specifications. Contractors should also inspect the finished products regularly and make any necessary adjustments. Creating mix designs for specific needs is also a key strategy for mastering concrete mix design.

Step-4 Selection of Cement Content for Mix

This helps to ensure that construction projects are completed according to the highest standards. By mastering concrete mix design, construction professionals can benefit from improved work efficiency, cost savings, and better quality control. Ultimately, this will lead to the successful completion of construction projects and improved customer satisfaction. Once the mix design has been created, it is important to establish quality control processes to ensure that the mix is regularly tested and monitored. This includes testing for the slump, air content, water-cement ratio, strength, and other qualities. Quality control should also be applied during the mixing and pouring of the concrete and during the curing process.

TYPES OF CONCRETE MIX

MIX directly imports of one of a kind unique found objects and furniture from around the world and produces a wide range of custom lighting, furniture and accessories. As we assumed the aggregate is a saturated surface dry condition, therefore no correction is required. Properly proportioned mixes will remain beautiful for many years. Use this handy concrete calculator to quickly calculate how many yards or bags of concrete you'll need for your project.

Recommended mix proportion of ingredients for grade of concrete M25:

The standard for designing a concrete mix is ACI 211.1, Proportions for Normal, Heavyweight, and Mass Concrete. Like most ACI committee reports, this document is excellent, albeit highly technical. If you want more detail, written in a more user-friendly way, get a copy of the Portland Cement Association's Design and Control of Concrete Mixtures; that's the bible for concrete mix design. Simply put, the concrete mix design means to find the types of materials to be used in the concrete mix in addition to their quantities. Nominal mix concrete can only be used in ordinary concrete constructions involving concrete grades not higher than M20. Design mix can be used for all the grades but it is generally used for M 25 and above grades.

Depending on the project, the resources required may vary; however, several common resources are required for any concrete project. Understanding and implementing these strategies makes it possible to master concrete mix design and achieve quality construction. Proper planning, knowledge, and attention to detail can ensure that projects are completed on time and within budget while also providing the end user with a higher-quality product. Concrete mix design is a technique used to determine the proportions of the ingredients needed to produce a concrete mix of desired properties. It is a complex process that considers the materials' properties, the environmental conditions where the concrete will be placed, and the desired quality. On the other hand, controlled concrete refers to the concrete mix that is tested and approved by a testing laboratory to meet specific strength and other performance requirements.

Without a timeline or goals, there is no way to measure progress and ensure that concrete mixes are being created promptly. Contractors can use the timeline to create realistic goals and stay on track. Mastering concrete mix design can also help contractors save money on their construction projects. This is because creating an effective mix design requires accurate calculations. Contractors can use the right materials for their projects with a precise mix design.

It’s a throwback to a simpler time when the family was the heart of a home. This is more about our view of home than a specific design style. We say it time and time again, but Richmond American’s appointments with a design consultant are complimentary and make the biggest difference when you’re going through the selection process. After all, mixing interior design styles is easy when you have a professional to guide you! This trusted resource is different than what you may experience with other builders. This video will give you a better idea of what to expect every step of the way.

Optimization design of rubberized porous asphalt mixture based on noise reduction and pavement performance - ScienceDirect.com

Optimization design of rubberized porous asphalt mixture based on noise reduction and pavement performance.

Posted: Mon, 31 Jul 2023 07:00:00 GMT [source]

Cool-Toned Watercolor Swirls

The selected PCC mixture should be the one that, based on test results, best satisfies the mix design objectives. Log in to TheConstructor to ask questions, answer people’s questions, write articles & connect with other people. Control flow concrete has a slump between that of conventional concrete and self-consolidating concrete.

A unique combo can create visual interest you’ll love for years to come. Placeability is simply the traits that the wet or plastic concrete has that allow it to be placed and finished. Placeability includes a mix that doesn't segregate but that can be consolidated. The classic way to measure placeability is slump, although two different mixes can have the same slump and behave very differently depending on the aggregates, the air content, and the admixtures. That is, they seek to combine the PCC constituents on a volume basis (as opposed to a weight basis). Volume measurements are usually made indirectly by determining a material’s weight and specific gravity and then calculating its volume.

Combining the right materials in the right proportions and ratios is key to creating a concrete mix that produces excellent results. As such, mastering concrete mix design is essential for any construction project. Doing so offers several advantages, such as improved work efficiency, cost savings, and better quality control. Creating a concrete mix design involves identifying the desired properties of the concrete mix and determining the proportions of the ingredients needed to produce it. The properties are generally defined in terms of strength, workability, durability, shrinkage, and other characteristics of the concrete mix. Mix design selects, combines, and proportions different concrete components to obtain the desired performance.

The unit weight of freshly mixed concrete is stated as a weight per volume. Corrosion inhibiting admixtures chemically mitigate the corrosive action of chlorides (often found in water) on reinforcing steel and prestressed strands in concrete. These design factors – function, cost and aesthetics – are mixed together in different ways in order to appeal to different target markets .

Durability is achieved by getting a low-permeability, low-shrinkage concrete that has the proper amount and distribution of entrained air. Durable concrete must resist freeze-thaw action and prevent chloride from penetrating to the reinforcing steel to contribute to corrosion. The unit weight and the yield are two additional factors that must be taken into account while trial mix proportioning. The yield is computed by dividing the total weight of all the components batched by the unit weight of the freshly mixed concrete.

When creating a mixed design, it is important to consider the various materials that make up the concrete. The aggregate should be chosen according to size, shape, and physical properties. The cement should be chosen for its strength and ability to set the concrete. The water content should be carefully measured, and the correct proportions of water and cement should be used for the best results.

No comments:

Post a Comment